Introduction

Schiphol

Amsterdam airport is Europe’s fourth-busiest airport. Handling about 50 million

passengers and 1.5 million tons of freight per year. It is often ranked among

the world’s best airports by the Skytrax passenger survey. Producing that sort

of quality 24 hours a day, seven days a week imposes high demands on the

infrastructure and services, including Schiphol’s network.

Problems

§ According

to a 2009 LATA CATS survey. Moreover, mishandled baggage is a $2.5 billion

problem for this industry every year.

- Annually effect about 51 million passengers travelling through Schiphol airport alone.

Goals

§ Realize

a monumental 1% maximum loss of transfer baggage (against the initial 22

million lost baggage);

- Increase capacity from 40 to 70 million bags; and

- Reduce cost per bag without increasing wait time.

Functions

of System:

Q1:

How Many Levels Of Complexity Can You Identify In Schiphol’s Baggage Conveyor

Network?

There

are 3 levels of complexities for schiphol’s baggage conveyor network:

Ø 21kilometers

of transport tracks,

Ø 6

robotic units, and

Ø 9,000

storage capacitors,

(No

extending the system with more surfaces)

Schiphol's

involved gigantic baggage conveyor network that includes 21 kilometers of

transport tracks, 6 robotic units and 9000 storage capacitors, all behaving as

one system. Extending the system with more surfaces is not possible given the

land conditions surrounding the airport. The baggage conveyor network goal

is to have the right bag must be at the right place at the right time.

Network

must perform several key roles that are moving bags from check-in area to the

departure gate, move bags from gate to gate, move bags from the arrival

gate to the baggage claim and plan and control peripheral hardware and

software. System involves a wide variety of sensors, actuators, mechanical

devices and computers and this network uses over 3 million lines of source

code. Some advance technology used in baggage-handling system includes

destination-coded vehicles (DCVs), automatic bar code scanners, radio frequency

identification (RFID) tags and high-tech conveyors equipped with sorting

machines. Baggage should move from its current location to its destination

before travelers do. Further complications shows that all of this must be

available and robust that are it must operate 99.99% of times while being able

to minimize loss or damage in that 0.001% of time it doesn't.

Q2:

What are the management, organization and technology components of Schiphol’s

baggage conveyor network?

Management

Manager sets

organization strategy for responding to business challenges. Manager has

estimated the budget for renewing the baggage control system is amounting $1.0

billion over a period of about 10 years.

Organization

1.

Hierarchy

of authority

Ø Management

and the employees to be working toward the same vision

Ø Different

task for employee according to their authority e.g controller, security and

maintenance worker

Ø Training

all employees from the earliest stages of the project, and doing so in the most

hands-on way possible.

Ø Employees

were to be trained about managing a robot to handle the baggage process.

2.

Separation

of business process/operation

Ø When

the customers arrived at check in desk their bags are tagged

Ø The

tags contains the flight information/bar code/FRID that all of the computer in

the baggage handling system can read.

Ø When

computers in the system scan the bar code/detect the RFlD, they process the

information it contains and determine where to send your bag.

Ø After

being scanned (at least) once, the system always knows where the bag is at any

point, and is able to redirect it based on three parameters: (a) time of its

flight; (b) priority: (c) size.

3.

Unique

business process

Ø Driving

a major effort to increase baggage processing capacity on the strength of

intelligent routing and optimization.

Technologies

1.

Networking

and telecommunication technology

Ø 3

million lines of source code

Ø Networks;

the internet

2.

Plan

and control peripheral hardware and software

Ø wide variety of sensor, actuators, mechanical

devices and computer

3.

Advanced technology

Ø

Baggage- handling systems (includes

destination-coded vehicles (DCVs))

Ø

Automatic bar code scanners,

Ø

radio-frequency identification automatic

(RFID) tags,

Ø

high- tech conveyors equipped with sorting

machines.

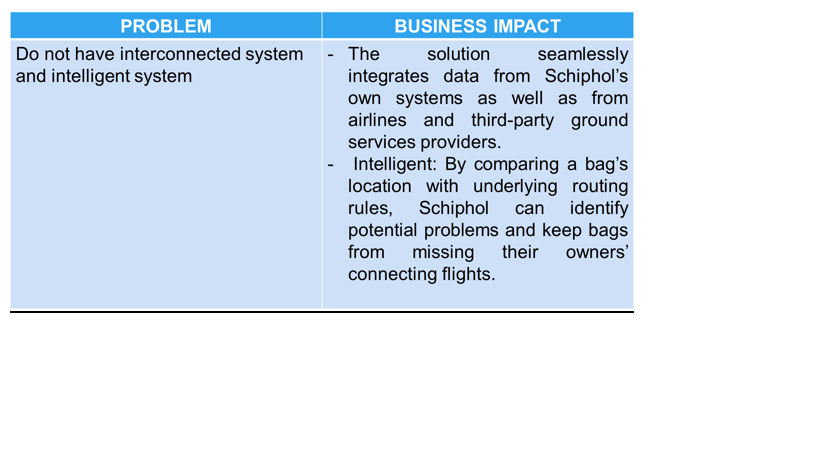

Q3: What is the problem that Schiphol is trying to

solve? Discuss the business impact of this problem?

The problem they are trying to solve is the increase

efficiency in baggage handling in the Schiphol International airport, in

Amsterdam, the Netherlands. Mishandled baggage is a $2.5 billion problem for

industry every year and this problem may annually affect about 51 million

passengers travelling through Schiphol airport alone. With the new system, the

manager of Schiphol estimated this system operate 99.9%of times while being

able to minimize loss and damage in that 0.01%. This system is extremely

expensive, but if implemented successfully it can save 0.1% of $2.5 billion.

Q4: Think of the data that the network uses. What

kinds of management reports can be generated from that data

Based on this case study we can conclude that the

management of Schiphol International airport has driving the major effort to

increase baggage processing efficiency and capacity on the strength of

intelligence routing and optimization.

No comments:

Post a Comment